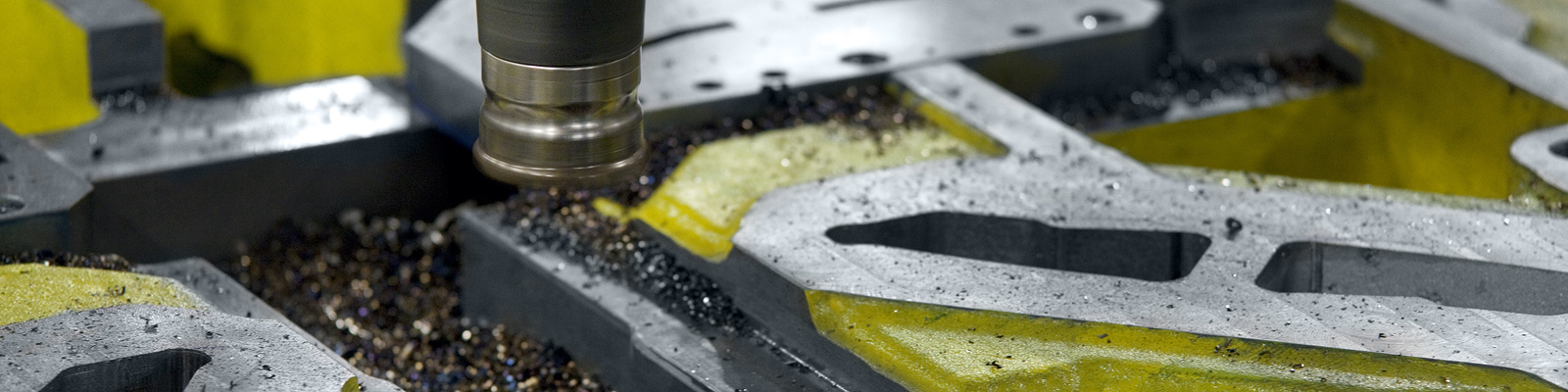

Large CNC 5 – 7 axis milling stations are indispensable for our type of specialization. The combination of our milling stations enables us to produce various types of tools to the required sizes and precision demanded by engineers and designers.

Technical equipment

Milling stations

Modelling department

The production of large polystyrene models and models made from modelling materials required to support the tool manufacturing processes.

Tool works

Parts are treated by grinding and polishing so that everything fits together perfectly. Assembly and testing is the final process of the majority of tooled and assembled products. Our experts are always present at the first use of the new press tool.

Laser technologies

We use 3 – 5 axis lasers to cut sheet metal and pressed parts. These lasers are capable of meeting our requirements on precision, shape and leaving the edges and material of the parts undamaged. A welding and quenching robot is used to complete the assemblies.

Assembly

The assembly workshops are equipped with latest technologies and equipment satisfying the requirements of the automotive industry.

Press shop

We are fully equipped for cold and hot form pressing, this makes it possible to produce deep-drawn parts. We press sheet metal from aluminium alloys and high strength metals.

Measuring and scanning

A comprehensive and extensive assortment of measuring instruments is available, from small individual devises for measuring the smallest of components up to complex measuring systems including 3D scanning and an optical scanning system capable of measuring the largest of vehicles. All are kept in top condition by our highly trained staff maintaining the well implemented metrological guidelines. Regular calibrations of measuring instruments are carried out ensuring that these required precision tests and validations are in harmony with the requirements of our customers.

Engineering, programming

Our software and hardware equipment mirrors the software standards of our customers. It is not merely the equipment, but also the know-how and experience of our engineers and NC programmers that is the key factor to the success of this department as well as the entire company.

Contacts

EBZ Hoffmann s.r.o.

Dědina 959

687 22 Ostrožská Nová Ves

Česká Republika

e-mail: info.cz@ebz-group.com /

Sales department: Tel. +420 572 420 644

EBZ Group GmbH: e-mail: info(at)ebz-group.com / Tel. +49 (0)751 886-0

We use state-of-the-art machinery and equipment. Our engineers and NC programmers use CAD/CAM software. We use 5 to 7 axis CNC milling stations. 5 axis lasers are also used for cutting various shapes. The prototype press shop is equipped with presses with sufficient parameters to cater for any automotive panel. The assembly stations are equipped with modern equipment meeting the strictest requirements of the automotive industry. We are also equipped with a highly precise tool-making grinder to support the manufacture of measuring aids and fixtures plus 3D measuring instruments, optical scanning systems are also used for accurate measuring.